Customized Product Solutions

Industry Focused Expertise

Technical Know-How

Service & Support since 1954

Rawson, Inc. is a trusted provider of industrial distribution solutions, specializing in instrumentation, valves, and controls. With service centers across Texas, Louisiana, and Oklahoma, we combine deep inventory with strong technical expertise close to our customers.

SERVICES AND SUPPORT

Engineered Solutions

Every facility has unique challenges, and that is where engineered solutions make the difference. Instead of forcing a one-size-fits-all product, we take the time to understand your process conditions, safety requirements, and long-term maintenance goals. Our engineers map out drawings, material lists, and specifications that fit the way you operate. From control panels to instrumentation packages, we handle the details that keep a project moving: approvals, testing, documentation, and startup support. Access to proven manufacturers and a strong supply chain means fewer delays and a better fit. Whether it is a simple skid package or a complex multi-system integration, our focus is practical design that installs smoothly, performs reliably, and holds up for years of service in demanding environments.

Automation & SCADA Programming

Reliable automation does not come from copying code; it comes from listening to operators and building systems that match plant operations. Our programmers create PLC, HMI, and SCADA solutions that keep plants running safely and efficiently. That means clean logic, organized tags, easy-to-read screens, and backups you can trust. We also tackle migrations from outdated platforms, helping you modernize without endless downtime. Communication protocols such as Modbus, EtherNet/IP, Profibus, and OPC UA are second nature to our team. We know the quirks and how to make them work together. Whether it is a single machine controller or a plant-wide SCADA network, we deliver code and graphics that operators actually understand. The goal is confidence that your system will run every shift, every day.

Instrument Service & Repair

Instruments are the eyes and ears of your operation, and when they fail, you lose trust in your data. That is why our service technicians focus on quick, reliable repairs and calibrations. We work both in the field and in-shop, handling transmitters, gauges, switches, recorders, and more. Every job comes with traceable reports so you know what was adjusted, replaced, or restored. Our crews do not just swap parts; they also check installation, wiring, and impulse lines to catch root causes. If audits or compliance records are a concern, we maintain schedules and documentation so you are ready when inspectors arrive. With access to replacement inventory and years of hands-on experience, we help you keep accurate readings and dependable control without costly surprises.

Inventory & Materials Management

Downtime often starts with missing parts. Our inventory and materials management programs are designed to prevent that problem before it happens. We review your usage patterns, critical spares, and lead times, then build stocking plans that balance cost with availability. Options include vendor-managed inventory, on-site cribs, kitting for turnarounds, and consigned stock to fit the way your team works. Regional warehouses keep depth on items like valves, instruments, actuators, and fittings so crews do not waste time waiting. Reports show stockouts, slow movers, and overall spend, making planning easier for everyone. When outages or projects come up, we pre-stage kits and track replenishment daily. The result is fewer surprises, shorter downtime, and more confidence that the right part is always within reach.

Product Specialism

Choosing the right product is not always about price; it is about knowing which option will last in your process conditions. That is where our product specialists step in. They understand materials, ratings, certifications, and sizing details that matter when reliability is on the line. Instead of handing you a catalog, they ask the right questions and then recommend parts that fit the first time. Specialists also help with drawings, submittals, and documentation to keep projects moving without delays. If something is on backorder, they know suitable alternatives that meet standards. With access to leading manufacturers and a broad inventory, they bridge the gap between technical knowledge and availability. Their support helps prevent costly misapplications and keeps projects and MRO work on track.

Steam Trap Surveys

Steam traps may be small, but when they fail, the losses add up quickly. Our steam trap surveys are designed to pinpoint exactly where energy, dollars, and reliability are being lost. Technicians walk your system, test traps, record conditions, and note whether each is working, failed open, or failed closed. We also check surrounding piping, insulation, and condensate return health. The result is a report that lists every trap, its status, estimated steam loss, and recommended action. You will see where repairs pay back fastest and which issues are most critical for safety. Beyond the survey, we can supply replacements, repair kits, and installation support. The goal is simple: reduce waste, recover capacity, and keep your steam system safe and efficient.

Technical Services

Sometimes what you need is not a product at all; it is experienced eyes on a problem. Our technical services team steps in when operations get stuck or reliability slips. We handle troubleshooting, commissioning, loop checks, burner management reviews, and site surveys. Every visit ends with clear documentation: findings, priorities, and next steps. That way, your crew knows exactly what to fix and why. We also help during turnarounds and startups, verifying interlocks, tuning loops, and backing up programs before equipment goes online. If you are chasing nuisance alarms, hidden leaks, or unexplained trips, we dig into the details until the cause is clear. With practical experience across industries, our team provides steady, informed support to keep your operation safe and dependable.

Valve Automation

An automated valve is not just an actuator bolted to a body; it is an engineered assembly that must fit your process. We provide complete valve automation packages including actuators, brackets, limit switches, solenoids, and positioners. Before anything is built, torque and material requirements are verified against service conditions such as corrosive fluids, hazardous areas, or high cycle demands. Assemblies are mounted, stroked, and tested so they arrive ready to install. Documentation includes drawings, torque sheets, and wiring details for easy hookup. If you need support in the field, our technicians handle commissioning, troubleshooting, and operator training. With strong manufacturer partnerships and stocked inventory, we can meet tight timelines without sacrificing quality. The outcome is dependable automation that makes maintenance easier and operation safer.

ENABLING CUSTOMER SUCCESS THROUGH EXPERT SOLUTIONS

Engineering Expertise and

Customized Solutions

With a team of in-house engineers, along with instrumentation and valve customization services, we can design and customize product solutions to help you solve complex problems and upgrade your facilities for the future. Our engineers design tailor-made solutions to help customers solve their difficult process-control problems from concept to providing technical support, long after the initial sale.

Simplified Ordering &

Customer Confidence

We partner with the world’s most respected and well-known brands. Additionally, we have dedicated quote and order teams who respond to all customer inquiries and quotes as fast and efficiently as possible. The team provides ease of ordering by delivering fast customer attention, swift action, and access to product and application knowledge to ensure the best product offering specific to your individual needs.

Engineered Valve Automation

and Assembly

Through our valve automation capabilities, Rawson customers receive a complete valve package – control or shutoff valve, actuator, and valve accessories – that is assembled, tested, and ready for installation, along with complete documentation of engineering drawings for assemblies in both standard and custom valve configurations.

PRODUCTS & SERVICE SOLUTIONS

From designing and planning to testing, implementation, operation, and maintenance, Rawson will be there to ensure your success.

Analytical

Analytical

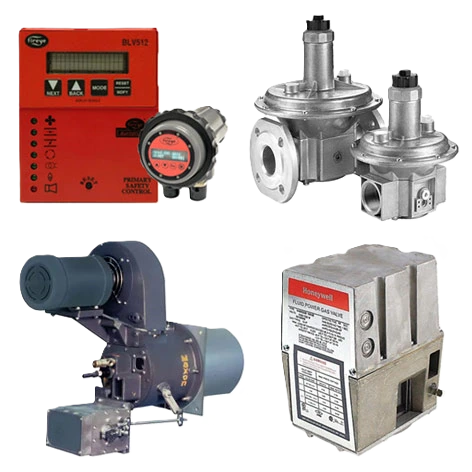

Combustion

Combustion

Filtration

Filtration

Industrial Automation

Industrial Automation

Instrumentation

Instrumentation

Steam & Energy

Steam & Energy

Valves & Actuation

Valves & Actuation

Our Core Values at Rawson

Strength

and Security

With over 100 years of experience, Rawson delivers reliable, secure industrial solutions building lasting partnerships and a strong foundation rooted in trust, expertise, and long-term customer commitment.

Comprehensive Solutions

Rawson offers a complete range of industrial products and services, providing tailored, integrated solutions that help businesses improve performance, reduce downtime, and operate more efficiently across industries.

Strategic Growth & Expansion

Our growth strategy includes targeted acquisitions that strengthen partnerships, expand our reach, and open new market opportunities ensuring long-term value for Rawson, our suppliers, and our customers.

A United Family of Companies

We grow through alignment welcoming exceptional teams that share our values. Together, we build a collaborative, culture-driven organization focused on unity, shared success, and continuous improvement across all regions.

RAWSON MANUFACTURERS