STF Self-Cleaning Screen, Disc and Microfiber

FMA 1000

Devices in the STF 1000 Series are hydraulically operated automatic mesh filters which have been designed for demanding filtration tasks with low flow rates in municipal and agricultural applications. The hydraulic operating system and ability to operate at very low flow rates, due to low cleaning water consumption, make the 1000 Series an ideal solution for applications where no power is available.

Related Documents

FMA 2000

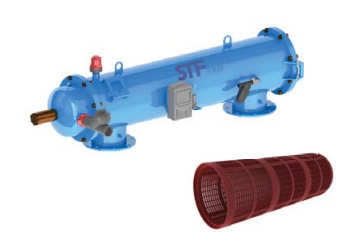

The range of STF automatic mesh filters has been designed to meet your filtration needs, such as drinking water facilities, desalination plants, food industry, cogeneration plants, chemical industry, cooling towers, field irrigation, golf courses, and physical barriers against zebra mussels, among others.

Related Documents

FMA 4000

The range of STF automatic mesh filters has been designed to meet your filtration needs, such as drinking water facilities, desalination plants, food industry, cogeneration plants, chemical industry, cooling towers, field irrigation, golf courses, and physical barriers against zebra mussels, among others.

Related Documents

FMA 4000E

STF 4000E series automatic electric screen filters are designed to optimize filtration solutions in electrical installations. It incorporates a new cartridge to optimize the surface of filtration, allowing greater flow rates. Its electrical operation system and its low cleaning -ater consumption make the FMA-4000E the ideal solution for applications where energy is available.

Related Documents

FMA 7000

FMA-7000-UV filters with self-cleaning screen are electrically operated filters with disinfection treatment by means of ultraviolet lamps, specially designed for low levels of filtration and disinfection treatment for low flow rates in municipal and industrial applications. They combine the action of filtration with disinfection in a single piece of equipment, decreasing the space of the installation and increasing the simplicity of the system.

Related Documents

FMA 10000

The range of STF automatic mesh filters has been designed to meet your filtration needs, such as drinking water facilities, desalination plants, food industry, cogeneration plants, chemical industry, cooling towers, field irrigation, golf courses, and physical barriers against zebra mussels.

Related Documents