TLV

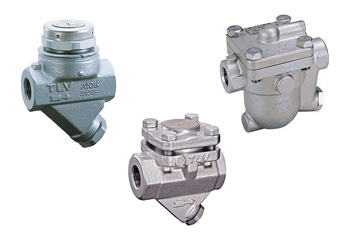

Steam Traps

Steam traps can be divided into three general categories based on their operation mechanism: mechanical, thermodynamic, and thermostatic. TLV manufactures all three of these types of steam traps. Our extensive product line-up makes it possible to select the optimal product to suit your objective or application. Each trap offers the highest level of energy conservation in its class.

Trap Valve Stations

TLV offers three universal connector styles for mounting steam traps: standard universal connector, bellows-valve trap station (1 or 2 isolation valves), and piston-valve trap station (1 or 2 isolation valves).

Manifolds

Manifolds suitable for use on steam supply branches and for convergence condensate from trace lines, etc.

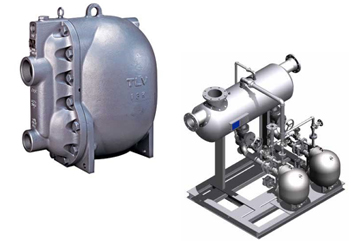

Condensate Recovery Pumps

The PowerTrap® is a pump that transports condensate powered by pressure from steam or compressed air without the use of electricity. It is ideal for use in open or closed systems, which collect condensate from steam-using equipment for the purposes of recovering heat energy and recycling treated water.

Separators & Pressure Reducing Valves

TLV Cyclone Separators achieve a remarkably high separation efficiency of 98%. The integral Free Float® steam trap discharges continuously and features three-point seating for a tight seal. Separators help to ensure high-quality steam or air free of condensate, increasing productivity and product quality.

Condensers/Exchangers

TLV offers an atmospheric waste-heat steam condenser heat exchanger to eliminate flash “steam clouds” and provide hot water for use elsewhere.

Testing

TLV’s TrapMan® testing device is the only device that is third-party verified to ISO5841 and ASME PTC39-2005 for accuracy. TM5NU is available for customer purchase and Trapman® software is licensed annually. Rawson EM&T will survey steam traps at the customer’s site using a TN5NU if desired–or Rawson EM&T will survey a customer site with our TM5NP.

Surveys

Maintaining high-quality steam for all steam users can greatly impact plant safety, reliability, productivity, and environmental targets, impacting site financial success. Routine steam trap testing and trap repairs are critical to keep steam systems operating at peak performance. Rawson’s EM&T division has the technical expertise and tools required to provide accurate steam trap evaluations and easily understood reports with information to manage the steam trap population while prioritizing repairs. All EM&T members are TLV TrapMan® factory trained and certified and have 10+ years of steam trap testing experience used in a variety of applications.

Steam Application Training

Every month, steam users are trained in our classrooms or on site on best-practice methods to manage steam and condensate systems.

Accessories

Strainers, sight glasses, and a variety of other products ancillary to steam traps and other valves.