McMenon Engineering

Orifice Plates

Orifice plates are the simplest of the DP flow-measurement devices. Inexpensive to replace and available in a range of materials, they are an ideal choice for applications where permeant pressure loss is not a significant factor. Devices based on orifice plates remain one of the bestselling flow metering technologies. As well as measuring flow, they are used to restrict the flowrate to a certain value or to reduce the pressure at a certain flowrate. The technology is well-understood and thoroughly proven and is available from McMenon in a wide range of designs to suit most applications. From simple plates to metering runs, McMenon has an orifice plate, union, or orifice carrier for all orifice applications – simple flow measurement, flow restriction, or pressure reduction.

Wedge Meters

The McMenon wedge meter product range is adaptable to almost any process condition or installation requirement. Wedge meters are particularly suitable for fluids that are dirty, viscous, abrasive, or have a tendency to foul, providing accurate measurements and resisting conditions that would normally wear the sensitive measurement surfaces found in orifice plate, turbine and cone meter, or positive displacement meters. In addition, they have the widest flow range of any DP-based flow device and require shorter upstream and downstream straight pipe lengths.

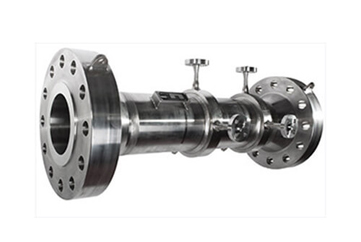

Venturi Meters

Venturi tubes offer excellent resistance to wear and consequently require virtually no maintenance. They have a very long service life, which is typically the whole life of the plant at which they are installed. They produce a low net-pressure loss and therefore reduce energy costs by typically 20 to 25%, with a consequent reduction in greenhouse gas emissions.

Averaging Pilot Tubes

Being insertion devices with a relatively small aspect ratio, Pitot Tubes incur a very low-pressure loss and are also very economical both to purchase and install, especially in larger pipelines and rectangular ducts. Pilot tubes are also available in retractable versions, allowing insertion and withdrawal from a pipeline without draining the process fluid. Accuracy and stability, proven across the industry spectrum, pilot tubes have unique sensor-design features, offering more accurate and more stable measurement over a very wide flow range. Pilot tubes create a pressure loss many times lower than that of other DP devices, meaning that energy costs incurred in restoring the lost pressure are minimal. Installation is also much simpler as it typically only requires a single hole in the pipe wall.

Flow Nozzles

The flow nozzle is used for high-velocity flow measurement where erosion or cavitation would wear or damage an orifice plate. It does not rely on a sharp edge (which can degrade over time) for accuracy; therefore, it offers excellent long-term accuracy and is often used for flow testing in steam-raising plants. The discharge coefficient of a flow nozzle is such that a nozzle can measure approximately 55% higher flow rates than an orifice plate with a similar beta ratio and design differential pressure. In the case of steam measurement, the pressure loss may not be significant as the effect is to beneficially heat the steam slightly.